Customised Services

In the competitive landscape of health and nutrition industries, our technical prowess directly determines its ability to deliver high-quality products consistently. By leveraging cutting-edge technologies such as chelation, granulation, liposome encapsulation, microencapsulation, micronization, and nutrient premixes, forward-thinking companies ensure superior product performance, stability, and scalability. Here’s how these technologies synergistically enhance supply chain resilience and customer satisfaction.

Enhancing Bioavailability and Stability

Chelation binds minerals (e.g., iron, zinc) to organic molecules (like amino acids), improving their absorption and reducing interactions with other ingredients.

Impact on supply:

Chelated minerals resist degradation during processing and storage, ensuring products meet label claims throughout their shelf life.

Reduced waste:

Enhanced stability minimizes batch failures and recalls.

Example:

Iron bisglycinate (a chelated form) avoids gastrointestinal side effects, making it ideal for prenatal supplements with high compliance rates.

Optimizing Production Efficiency

Converts fine powders into uniform granules, improving flowability and compressibility.

Faster production:

Granules enable high-speed tablet pressing and capsule filling, reducing manufacturing time.

Lower costs:

Minimizes material loss and equipment downtime.

Example:

A granulated vitamin C blend ensures consistent dosing in effervescent tablets, accelerating large-scale production.

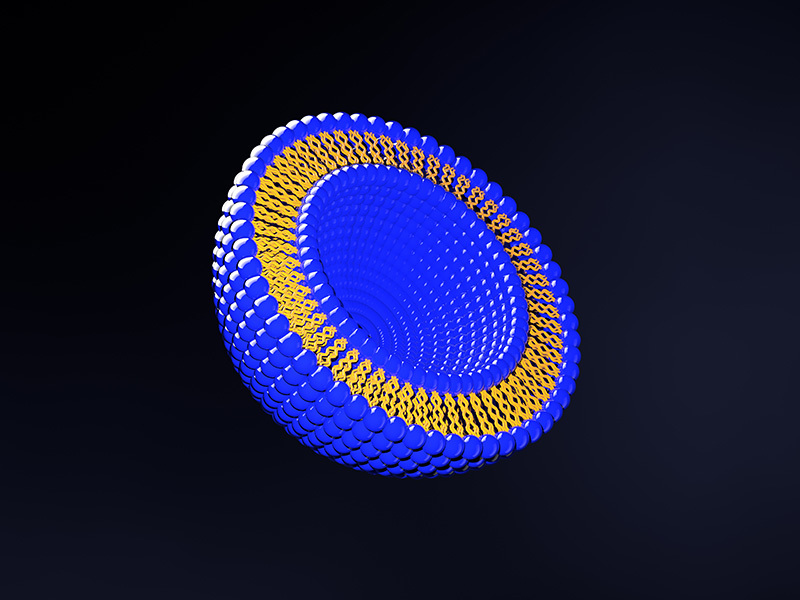

Encases nutrients (e.g., vitamin C, curcumin) in phospholipid vesicles to enhance bioavailability and stability.

Extended shelf life:

Protects ingredients from oxidation and humidity.

Market differentiation:

Enables premium pricing for high-efficacy products.

Example:

Liposomal glutathione retains 95% potency after 24 months, meeting demand for anti-aging supplements.

Precision Delivery & Taste Masking

Coats ingredients (e.g., probiotics, fish oil) with polymers or lipids for controlled release and flavor masking.

Impact on supply:

Supports diverse formats (gummies, powders, RTD beverages).

Eliminates unpleasant tastes, broadening market reach.

Example:

Microencapsulated omega-3 powders enable tasteless inclusion in protein bars, expanding product applications.

Maximizing Nutrient Absorption

Reduces particle size to micrometers, increasing surface area and solubility.

Enhanced efficacy:

Improves absorption of poorly soluble compounds (e.g., CoQ10, resveratrol).

Cost savings:

Smaller doses achieve equivalent effects, reducing raw material costs.

Example:

Micronized curcumin achieves 10x higher bioavailability than standard extracts, meeting demand for potent anti-inflammatory supplements.

Pre-blends vitamins, minerals, and functional ingredients to precise ratios.

Quality control:

Eliminates batch variability, ensuring compliance with regulatory standards. •

Scalability:

Streamlines production for large orders without compromising accuracy.

Example:

A premix containing vitamin D3, calcium, and magnesium simplifies manufacturing of bone health supplements.